The rich history of Damascus steel has made it an attractive subject for straight razor enthusiasts. Its unique wavy patterns and exceptional strength have made it a legend in the world of metallurgy for centuries. In this article I’ll look into the differences between ancient and modern Damascus steel, its history, and its production methods–particularly with respect to modern straight razors.

Introduction to Damascus Steel

Damascus steel is a type of steel used for making edged blades (swords, knives, razors) and jewelry, to which the city of Damascus is famous and attributed. It has been manufactured for centuries using a process that involves layering and forging different types of steel together, creating unusual, attractive wave-like patterns. While modern technology has advanced the production of Damascus steel, the methods used by ancient craftsmen still hold some secrets that are yet to be unraveled.

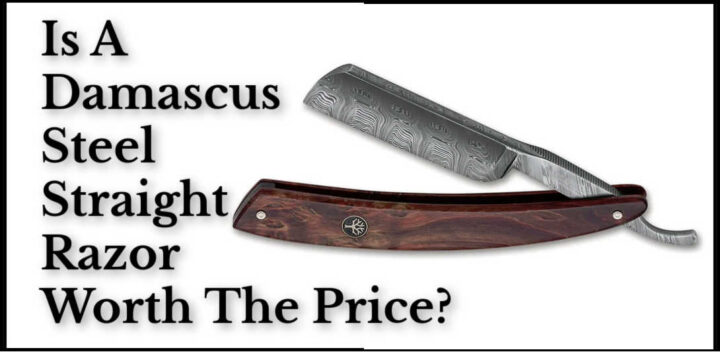

Examples Of Modern Damascus Steel Straight Razors

Here are some examples of modern straight razors that use modern Damascus steel. [Note: links are affiliate.]

Boker

Boker Damascus Curly Birch (via Grown Man Shave)

“The modern handle shape fits perfectly to the 6/8 inch wide blade made of Damascus steel with a French head and is completed by the fine Boker tree emblem, which is inserted into the handle by hand. With authentic Boker lase engraving in the blade passage, certificate of authenticity, and noble floating display. Handmade in the Boker knife manufactory Solingen.“

Thiers Issard

Thiers Issard Damascus 6/8″ Imitation Tortoise Shell (via Grown Man Shave)

“This razor uses powder metallurgical Damasteel (Ed. note: read more about Damasteel below). Two types of high carbon steel powders are rippled together, pressed and sintered. With this method you get a very fine structure of the material and a higher share of carbide than in the traditional made steel.“

Naked Armor

Naked Armor Esclabor Damascus Steel Straight Razor (via Naked Armor)

“Damascus steel is the forged steel of blades of swords smithed in the Near East. Characterized by distinctive banding patterns and mottling reminiscent of flowing water, sometimes in a “ladder” or “rose” pattern….

Being our heaviest razor, this straight razor blade is made of the toughest steel, resistant to shattering, and capable of being honed to a sharp to a resilient edge….

We crafted this blade with the best steel available in the world and with the highest hardness rating found in any straight razor to create the best face-to-shave ratio. We started by importing Damascus steel sheets with a hardness rating of 62-63 HRC.”

A Brief History Of Damascus Steel

Damascus steel has a rich history dating back to the pre-industrial era, where it was first produced in the Near East using techniques such as pattern welding and forging to create strong and flexible blades.

Origins And Development Of Damascus Steel

The origins of Damascus steel can be traced back to around 2000 years ago, with the first recorded production of these blades dating back to as far as 750 C.E in and around Syria. This ancient technique was initially developed by forging Wootz steel ingots, which were either imported from Southern India or produced locally in Sri Lanka or Khorasan. The name “Damascus” steel stems from its initial production center – Damascus, Syria – where artisans crafted unique swords renowned for their strength, flexibility, and distinctive wavy pattern.

The development of Damascus steel continued over many centuries; various unique alloys evolved using different varieties of steels. Ironsmiths had honed their skills on techniques like heating and cooling metals together to create an incredibly strong alloy. They also mastered innovations such as folding the billet multiple times during the forging process, resulting in alternating layers that contributed immensely to the metal’s hardness and flexibility.

However the exact techniques for creating this steel were lost over time, leading to the decline of its production.

Modern Technology in Damascus Steel Manufacture

In recent times, modern technology has revolutionized the production of Damascus steel. While ancient techniques utilized natural resources, modern technology has introduced new methods that incorporate special alloys, complex heat treatments, and advanced welding techniques.

The use of new methods in steel technology has enabled steel manufacturers to produce blades that are just as sharp and durable as their ancient counterparts. However, the traditional techniques that were used to create Damascus steel blades, including those involving secret organic materials and plant life, continue to be studied and analyzed in the hopes of expanding and improving upon the original material.

Comparing Ancient and Modern Damascus Steel

Genuine Wootz Damascus Steel

Comparative studies between ancient and modern Damascus steel have revealed interesting insights into the differences between the two. Thanks to modern technology, today’s Damascus steel is produced by welding together several types of steel and iron slices to form a billet. However, true Damascus steel from ancient times had a specific composition and grain structure that made it vastly superior to other blades of its time. Nevertheless, modern high-carbon steels made in the 19th century are also highly reliable and carefully formulated for predictable performance.

But what gave the ancient Damascus steel its unique properties remains a mystery. Some experts believe organic materials like camel urine were added during the forging process.

What About Damasteel?

Damasteel is both a company and a modern trademarked, patented powder steel process of making Damascus steel. The process of creating damasteel was developed in the early 1990’s by Swedes Per Billgren and Kaj Embretsen. Damasteel takes the traditional forging process of damascus steel to the next level by using powder metallurgical steel manufacturing.

Damasteel starts with a gas atomization steel making process where molten steel is forced through a nozzle and aerosolized. The resulting steel powders are created in a perfectly spherical shape with a high level of cleanliness and homogenous distribution of carbides. The powders are then collected in a canister, which is sealed, compacted, and bonded. There are no welds in the steel making it structurally an extremely strong steel.

Is Modern Damascus Steel Better Than Modern Regular Steel For A Straight Razor?

Damascus steel is gaining interest for high-end straight razors due to its reputed excellent quality, historical background, and aesthetic appeal. The unique pattern created by the layering and forging process also adds to the razor. However, whether modern Damascus steel is better than modern regular steel for a straight razor depends on the specific qualities of the steel used.

The most important factor to consider when selecting a steel for a straight razor is its ability to hold a sharp edge. A razor that loses its sharpness quickly will require frequent sharpening and may not provide a clean, close shave. Both modern Damascus steel and modern regular steel can be made to have excellent edge retention, but the specific type and quality of steel used will be the most important factor in determining performance.

Other factors to consider when choosing a steel for a straight razor include the razor’s durability, corrosion resistance, and overall quality. While modern Damascus steel can be an excellent choice for a high-end straight razor, modern regular steel can also be a great option if it is of high quality and has been properly heat-treated and forged.

Ultimately, the best steel for a straight razor will depend on a variety of factors, including the specific needs of the user and the qualities of the steel itself. Both modern Damascus steel and modern regular steel can be excellent choices for a straight razor when manufactured properly.

How To Tell Real Damascus Steel From Fake

A US $6 “Damascus Steel” Straight Razor From AliBaba

With the rising demand for Damascus steel, there has been an influx of fake or imitation Damascus steel in the market. Here are some ways to tell the difference between real Damascus steel and fake Damascus steel:

- Look for the pattern: real Damascus steel has a distinct and consistent pattern of banding and mottling that is created through the forging process. The pattern should be visible on both the surface and cross-section of the steel.

- Check the weight: authentic Damascus steel is typically heavier than its fake counterparts due to the presence of multiple layers of steel. If the item feels lightweight, it may be a sign that it is not genuine Damascus steel.

- Check the edges: real Damascus steel is known for its sharp edges and ability to hold a sharp edge. If the item you are examining has dull edges or is difficult to sharpen, it may be an indication that it is not authentic Damascus steel.

- Check for weld marks: authentic Damascus steel is made by welding together multiple layers of steel, which can leave visible weld marks or lines on the surface of the steel. If there are no weld marks or lines, it may be a sign that the item is not real Damascus steel. (This does not apply to Damasteel.)

- Check for rust: real Damascus steel is resistant to rust and corrosion due to the presence of high levels of carbon in the steel. If the steel shows signs of rust or corrosion, it may be a sign that it is not genuine Damascus steel.

- Check the price: authentic Damascus steel is expensive due to the labor-intensive process used to create it. If the price of the item seems too good to be true, it may be an indication that it is not real Damascus steel. Count on spending at least several hundred dollars for a modern authentic Damascus steel straight razor.

- Seek out reputable sellers: The best way to ensure that you are purchasing real Damascus steel is to buy from a reputable seller or manufacturer who has a proven track record of producing high-quality Damascus steel products.

It is important to note that there are different types and styles of Damascus steel, and not all of them will exhibit the same characteristics. If you are unsure whether an item is authentic Damascus steel, it is always best to seek the advice of an expert or a reputable seller.

About The Author: Otto Wright is a wet shaver and freelance writer.

Craftsmanship Magazine had an interesting article (with video) that made a good case for a modern rediscovery of Damascus steel: The Wootz Hunter.

A more recent video provides additional information.

Comments are closed.