[Note from the editor: caution, this post is image-heavy.]

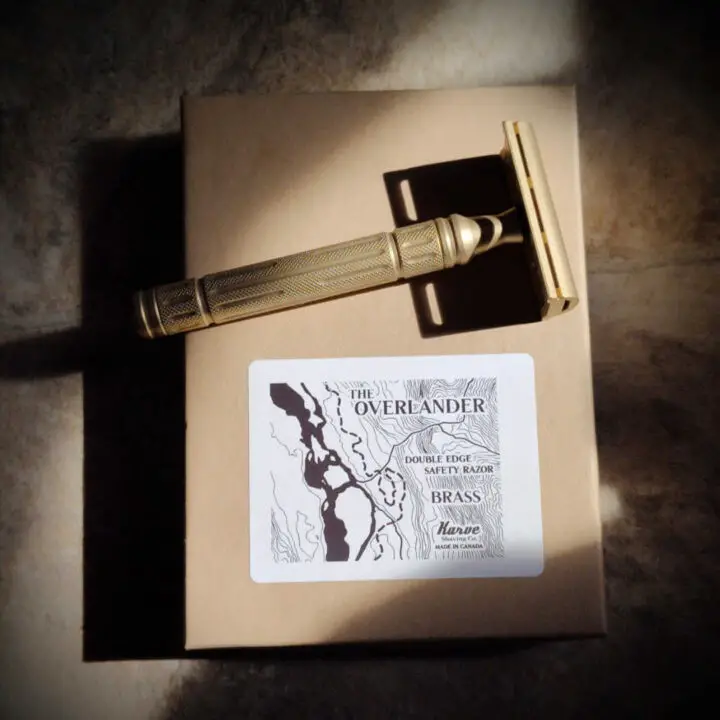

On a lark I recently purchased one of the famed Overlander razors from Karve Shaving Co. I’ve heard many good things about this razor, and after reading some online reviews and hearing its praises sung, I decided to investigate for myself.

The Famed Overlander In Brass

Ideally I gravitate towards razors in 316 stainless steel or titanium as my go-to favorite materials. Both resist corrosion quite well, they tend to be precisely machined, and they have good aesthetics. A win-win-win all the way around.

This time I decided to try something different, so I purchased an Overlander razor in brass, partially because this new material was a different foray for me, also because it was amongst the least expensive options available. Sometime later the product arrived in the mailbox with a nice handwritten note from Chris, and then the shave experimentation began.

As many others in our beloved wet shave community have similarly reported, the Overlander performs its job admirably, effortlessly fusing the neigh-impossible combination of efficiency and comfort. And it arrives at your homestead in your choice of many different materials: bronze, copper, brass, stainless steel, or aluminum.

Brass is the cheapest to acquire at ~$100 USD, so this was not a painful purchase. I briefly considered other options, but most other available materials are over double this price and personally I don’t care for the lightness of aluminum razors.

Speaking of, the first shave was quite sublime and almost perfect in execution. In spite of a fresh sharp blade, a longer 3.75 inch handle, and the razor weighing in at a cruiserweight 115g, I got an efficient, BBS shave with no discomfort. I was slightly gobsmacked because I expected spots and irritation when finished, yet I was dealt none with this somewhat hefty shaving instrument. Personally I find lighter titanium handles and or razors reduce discomfort and razor burn, but the precision and design of the Overlander gave me the best of both worlds. Yes, it really is that good.

As per my usual, I then set about doing a very light polish of the head cap and safety bar, along with some breaking of any nearby sharp edges.

Since brass is very soft, the matte bead blast finish comes away in no time, and a final mirror-like shine readily presents itself, as is the above.

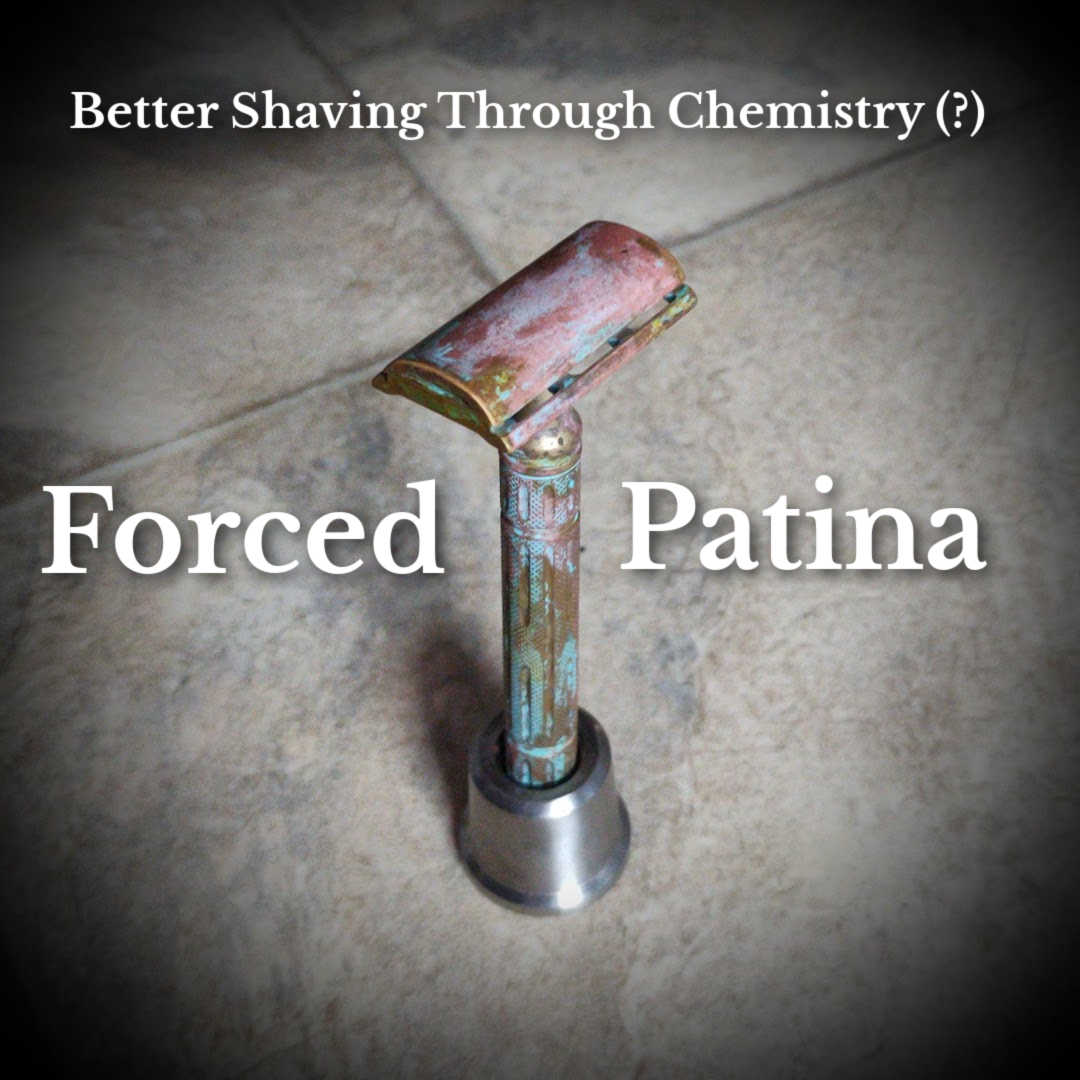

Artistry In Corrosion

As I observed the beginnings of patina spots building after concluding my first shave, thoughts of fun experimentation began to percolate in my mind. Since copper and its alloys of bronze or brass are reactive in the presence of oxygen and/or moisture, a tarnish readily forms which we call “patina“. In brass this is usually evident as a darkening of the material, as you see below.

However, in metal artistry this corrosion effect may be generated in other colors using different chemical reactions, and after some online research I discovered a rather pretty light blue/green patina might be brought about by applying copper(II) sulfate to brass (or bronze or copper). There are other options but this is one of the go-to solutions for achieving this artistic effect: https://en.wikipedia.org/wiki/Copper(II)_sulfate.

I purchased some of this material from Amazon (Editor’s note: affiliate link) and then began using my Beloved Overlander as a chemical “guinea pig”.

Mind you, this was done in a well-ventilated room while I was wearing rubber gloves, and the razor resided upon an old dinner plate with a cracked edge which was put out to the pasture some time back. The small paintbrush was also exclusively reserved for this undertaking, and I also previously applied some petroleum jelly to the threads to prevent any undesired corrosion in these areas.

While I was quite pleased with the unique results, this left behind a mass of crusty crystalline precipitate on all the services I painted the chemical upon. While copper sulfate has moderate antiseptic qualities when applied directly to the skin, I don’t find it advisable to have this rubbing off tangible amounts on my face or head during the shave. Out came an old toothbrush and I vigorously scrubbed away the excess buildup.

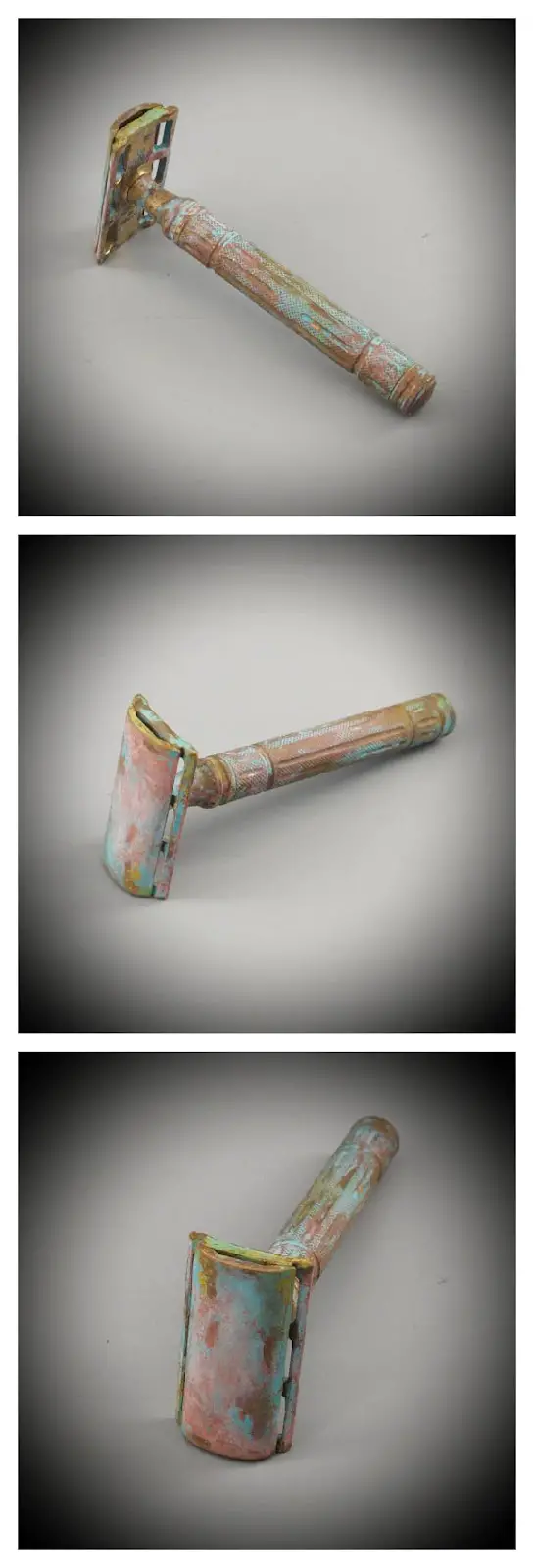

One Of A Kind Razor

Now we are getting back down to the bare metal! Some further cleanup and scraping away with my thumbnail produced a very beautiful distressed look on the surface chemistry. Instead of a boring old mere darkening of the metal from the aqueous environment alone, I now am the proud owner of a one-of-a-kind razor with a multi-hued patina on it. I see yellows and light copper tones alongside residual traces of light blue chemical remnants. It is elegant in a sort of “1990’s industrial music album cover art” fashion, and the distressed metal look is quite exceptional to behold.

I’m pleased to report the quality of the shave was maintained after the final touch ups. The “Technicolor Overlander” is still just as comfortable, forgiving and easy to use as it was before I started all of this chemically-induced silliness.

Shaves come away with blessedly zero irritation even when sporting a relatively sharp Voskhod blade, and the extra heft of brass helps the blade effortlessly plow through tough whiskers with nary an afterthought. Further shaves have darkened the exposed metal and the grooves in the handle now retain the most colorful aspects. I still have the “brass smell” with this razor, so when finished handling this or any current brass, bronze, or copper razor or workpiece, you are well advised to wash your hands.

A Colorful Summation

In closing, I urge you to consider looking at some of your razors not just as an instrument for shaving but also as functional art. Perhaps some similar chemical experiments are in your future? If so, the primary lesson learned I wish to convey is: limit your experiments and chemical modifications to the handle alone, and perhaps also the underside of the base plate. From there you might apply a clear sealant layer to preserve the coloring.

Good luck, and may your shaves always be comfortable!

P.S.: Don’t tell Chris from Karve about this little experiment; we don’t want him to lose his marbles over this. Just keep it our little secret, eh? 🙂

You have an interesting way to put a patina on your razor. The look of the razor in the hand probably looks better than the photo, which looks downright hideous. I myself have used lemon/lime juice (acetic acid) to put a forced patina on a brass razor.

Great article. Thanks

You ruined a nice razor. That’s rather sad.

This is a bullshit way to patina.

First, you do NOT polish before treatment. What’s the point? And besides, polishing increases corrosion resistance.

Secondly, that’s not a patina. That’s just a copper sulphate coating. Like paint.

Real patinas have nitrates, chlorides, sulphates & sulfides.

If you really want a patina, ready-made solutions are available in the market