Fendrihan Ltd. recently began selling a stainless steel 3 piece safety razor with a variety of stainless steel handles. The stainless steel razor at a budget price is something of a grail for manufacturers and consumers, and it’s been attempted before: Weber, for example, produced their head and handles beginning at $50 a few years ago. It was unsustainable, and Weber no longer sells razor heads.

The Idea

The idea is this: What if you could sell a razor at an affordable price and make it a Buy-It-For-Life item: that it was of such quality that it would last the user’s lifetime? What if for a little more money than the zinc alloy razors that are serviceable but fragile, you could have something really good? Zinc disintegrates in contact with water, and has a bad reputation for longevity if the chrome plating is compromised at all. Stainless steel and brass have no such risks, but brass is commonly plated, leaving it susceptible to plating damage.

Stainless steel razors commonly sell for $120-300ish from makers like Above the Tie, iKon, LASSco., and Wolfman. To have a regularly available production model for $39 USD is potentially a game changer.

Instead of machining out of stainless, which is very expensive, it appears from the surface texture to be Metal Injection Molding, where the molten metal is injected into a mold. Manufacturers using this process get precise results with the one upfront tooling cost, rather than the recurring machining costs. It may not always work out to be a huge savings (there are lots of variables in making a product) but it can potentially be one. At the $39 price point, it has to have worked out: Fendrihan is not in the business of selling products at a loss.

The company set out to make an affordable stainless steel razor, and rather than make consumers choose between comb and guard bar, or ‘mild’ or ‘aggressive’, they tried to provide all of the options in one razor.

Other razors have attempted this: The limited edition iKon SBS gave users a comb and bar, and a baseplate that flipped to offer mild and aggressive sides. The Rockwell, another stainless razor, provides their users with 3 baseplates that flip to provide 6 levels of ‘mild’ to ‘aggressive’ shaves. This goes back in history to the Bohin, a flippable baseplate razor from France in the mid-20th century.

Essentially, this razor wants to be all things to all people, in the best material, at an affordable price, so that it’s right for everyone in at least one way.

The Right Razor?

This should have been the right razor for beginners and experienced shavers alike. By setting out to manufacture in stainless steel and make two levels of aggression, it should have been a razor where everyone could at least find half of the head they like. It didn’t quite work out like that in my experience.

The point of a DE safety razor is to be able to efficiently and easily remove hair. That’s its job in life. Ideally, it does so without irritation, burn, pulling, or laceration.

Some people prefer a more mild razor, while some prefer a more aggressive razor. I define these terms to mean, a mild razor is forgiving, and if there’s a little too much pressure, or variance in angle, you won’t experience burn or cuts. An aggressive razor almost anthropomorphizes, it wants to peel back layers of skin, and your attention is required to convince it not to do so.

Fendrihan writes on the product page,

“With a combination open-close comb head, you choose the shave. Do you want the forgiveness of the Merkur 34C or 38C? Use the straight bar guard. Feeling more adventurous? Turn to the open comb side for a shaving experience akin to the Muhle R41 or the Joris razor.”

The Experience

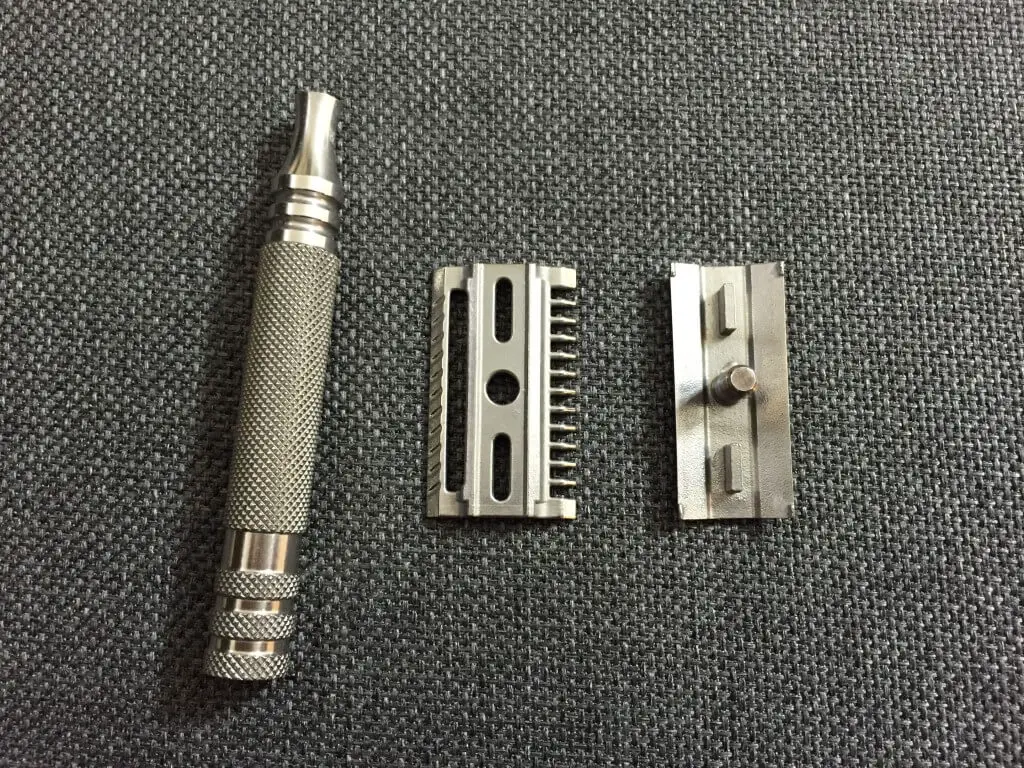

My experience didn’t quite work out like this. In my experience, neither side was forgiving. The comb side was actually gentler than the bar side. Both required a great degree of focus and sensitivity, but the bar side was inclined to cause weepers and lacerations while the comb did not. It was possible to do a 3 pass shave and hear silence on the last pass with the comb, flip to the bar side, repeat the pass, and hear hair still being cut. The bar side was inclined to cause razor burn on the upper lip on the first with the grain pass. This is an extreme razor.

I used the Fendrihan Adventurer model, which is the same as the Scientist, Artist, and Ambassador models. These differ in handle only. I used it with Feather, Astra, Gillette Nacet, Silver Blue, and Personna Lab Blue blades. It was near-uniformly harsh with all of them, delivering the best of the shaves with the Astra SP.

Looking at the profile of the top cap and baseplate, and the razor looks like the angle bends steeper over the comb side, reducing expsoure – that would explain why it feels gentler. I grant that’s just eyeballing it under a macro lens, not measuring scientifically, but the experience doesn’t lie – the comb side is gentler, contradicting the Fendrihan web store copy’s assertion that the bar side should be easier-going.

In my recent experience, the comb side compares to something like, in terms of aggression, a LASS BBS-1, which is a lovely, well-made, machined safety bar razor. I’m not sure what to compare the safety bar side to.

Had it followed through on the promise of being as mild but efficient as the Merkur 34C Fendrihan name-checks on the store page, it would be a great razor for beginners as well as long-time users. As it is, it’s difficult to recommend it to beginners, which is a shame, because the price is so approachable for the beginner.

But Fendrihan’s done quite a few things correctly here: They’ve used all stainless steel as advertised. The handle looks and feels decent. The knurling isn’t sharp, but is grippy. The head has the somewhat pebbled surface you get from injection molding, but is smooth where it counts for precision. The blade is always straight, never wavy, and it aligns perfectly without adjustment everytime.

The Fendrihan Adventurer, Artist, Ambassador, and Scientist Stainless Steel Safety Razors are available for $39.95 from http://www.fendrihan.com

I would suggest that it’s worth doing a review of the Fendrihan Mkii. I find it to be as mild and comfortable as my DE89, but giving a slightly closer shave. Wouldn’t this make it suitable for a beginner?

I will check it out!

” Zinc disintegrates in contact with water,”

No it doesn’t, (galvanization?)

Zinc alloys are brittle at room temperatures. Thats the main problem a drop of a few feet on to a hard surface might spell the end of your razor. Apparently contamination of Zinc alloys leads to castings all but disintegrating from within. I imagine that’s were the dissolving zinc razor stories come from. Horror stories like this appeared on a modelling forum a few years ago, the chap making the castings had bought ingots of contaminated Zamac from ebay.

I could tell by the picture you posted with the blade loaded that it would be a rough shaver. Not sure it has to do with the gap at all; by the looks of it, I think it’s the exposure that is out of line.

Large gaps are not problematic as long as the exposure is small; the Tradere is a classic example. Even the famously mild Feather AS-D2 has a fairly good-sized gap.

Just one look at that picture would’ve been enough to convince me not to go near it, with or without the accompanying article.

Hi Randall,

You’re absolutely right, it’s not the gap, it’s the exposure of the sharp edge as it crosses an invisible line from top cap to base plate.

I sometimes wonder if I got a badly made one, but I’m not sure how that could be.

Personally I love the razor. I find the fit and quality to be excellent. I do not find it to be overly aggressive at all. I think the problem with most complaints on razors is that the reviewers use too many different razors and don’t find the sweet spot with some razors for shaving. All razors are different and use different angles for a smooth shave. I am 64yrs. old and not a shaving snob but take the time to figure things out.

Hi Dave,

What a great comment! Shaving is very much a personal experience, and what works well for some may not work at all for others. I’m glad the Fendrihan works well for you.

What’s interesting is that some razors work brilliantly for me the first time, so I disagree with your comment that I didn’t take enough time to find the sweet spot of the Fendrihan after giving it two weeks worth of daily use. I’m afraid I’m not ready to modify my position; this is not a razor meant for beginners when it’s priced for them. It doesn’t hit the target of the mild Merkur 34C that Fendrihan claims.

From: https://www.fendrihan.com/products/fendrihan-adventurer-full-stainless-steel-safety-razor

“Do you want the forgiveness of the Merkur 34C or 38C? Use the straight bar guard.” But it just wasn’t so in my use.

Since it is not symmetrical, if you turned the top cap 190 degrees might you not get what you are looking for from both bar and comb?

Correction – 180 degrees.

It’s a nice thought but no. The top cap is not symmetric but the base plate is. Rotating the top cap gives the same results. Besides, if that were true, if rotating changed its behavior, it should have been marked or indexed so it would be difficult to assemble incorrectly.

As a clarification, repeated injections of near molten metal into a mold under pressure has a deforming effect on the mold over time. My Weber PH came out of earlier production runs, and the baseplate is flat and there’s no wave to the blades. Webers from later production runs were not because the molds had been altered by repeated injections.

Both sintering and MIM leave a pebbled texture. MIM makes adherence to the mold easier, decreasing porosity a bit more than straight sintered parts. Controlling porosity in sintering can be done by decreasing particle size. Both MIM and sintering have been used effectively and although not as solid as CNC machined parts, there is much less waste than CNC. Over time molds used for both CNC and sintered parts affect the mold itself. I believe that caused the wavy blades in Webers which led them to abandon head production as retooling is costly.

Thank you for this explanation. I don’t mind going off into the weeds if I learn something. The surface of the razor looks and feels pebbled on much of the inner surfaces. I didn’t insert a good photograph of the surface, but you can see it in the zoomed image on the Fendrihan product page. Can you tell by looking which process it is? I’m inclined to say that it is sintered as you describe, but I’d like your opinion.

Good review, a small technical point is worth making. Pouring molten metal in a mold is casting. Metal injection molding is a variant of sintering. In sintering powdered metal is heated to near molten, and then injected into the mold. Under pressure there is linking of the powered metal pieces forming a single form. With MIM the process is similar, but a plastic powder is mixed with the powdered metal which facilitates the entry of the powder into the mold. The plastic burns off (radication), and the powdered pieces are fused like sintered parts. Might be a bit far in the weeds.

Comments are closed.