How do you know what works well for you when shaving? How did you come about your best? How well can you compare and contrast the performance of the blades you use and swap out on a regular basis? A blade is a blade is a blade, right?

Blade Consistency

When you examine the myriad of razor blade reviews on yee olde internets, what do you usually find? You get one man’s opinion as to how well that blade works for him alone. This is better than nothing but may not be the best guideposts as to what will work for you and your unique situation.

What if I could have you examine a few charts and graphs and get a better idea of what blades give you the most consistent results? If you stick with me throughout this short article I will explain why certain blades are more comfortable to work with and scientifically prove which blades are better.

Most of the data for this article comes from www.RefinedShave.com. The gentleman who has produced that wonderful webpage has brought scientific testing to the arena of double edge razor blades, so we might get a glimpse of how various brands and blades perform from the first time you pick them up until the time you recycle them. As a fair disclaimer, the author that webpage is an engineer, as am I also, but I’m not affiliated with him nor have I been in direct contact with him. We will simply examine the data that he provides and draw conclusions thereof.

I wish to draw the main conclusion here: Blade consistency – from start to finish – is the primary factor of your shaving comfort. Consistency is as important as edge sharpness, as we will discuss. All blades are sharp to varying degrees at one time or another, but not all blades hold their edge well through use.

First, some background is in order. There are 3 factors which affect blade performance:

- Blade grind.

- Blade coating.

- Blade toughness/edge consistency.

Coatings

We will bypass discussion on points of blade grind and material, as they tend to be proprietary per each manufacturer. Blade coating somewhat less so.

Most blades have a PTFE [Polytetrafluoroethylene, AKA “Teflon”] coating or similar polymer coating, to reduce friction and enhance comfort. Other coating components can include platinum and/or chrome plating. PTFE naturally has a low coefficient of friction, so it is very slick to the touch and almost self-lubricating. However, PTFE tends to be soft and wears out very easily, especially when coated on a slick surface – like that of a polished and ground razor blade – which is then exposed to abrasive materials like your whiskers.

This coating – whatever it is composed of – will usually last for part of your first shave before it is worn away, maybe longer depending on the preparation of the base metal, coating chemistry, and quality of bonding. Thereafter you get down to the “bare metal” of the blade itself. The cutting-edge will cut before the coating wears off, but as is it wears you will notice the blade changes “feel” as you go through your shave. This is why your first passes going with the grain [WTG] or across the grain [XTG] will feel different than your finish passes going against the grain [ATG].

For background on how the coating is applied – and how the razor blade is made – please consider viewing a YouTube video:

How Its Made – Double Edge Razor Blades

Sharpness By The Numbers

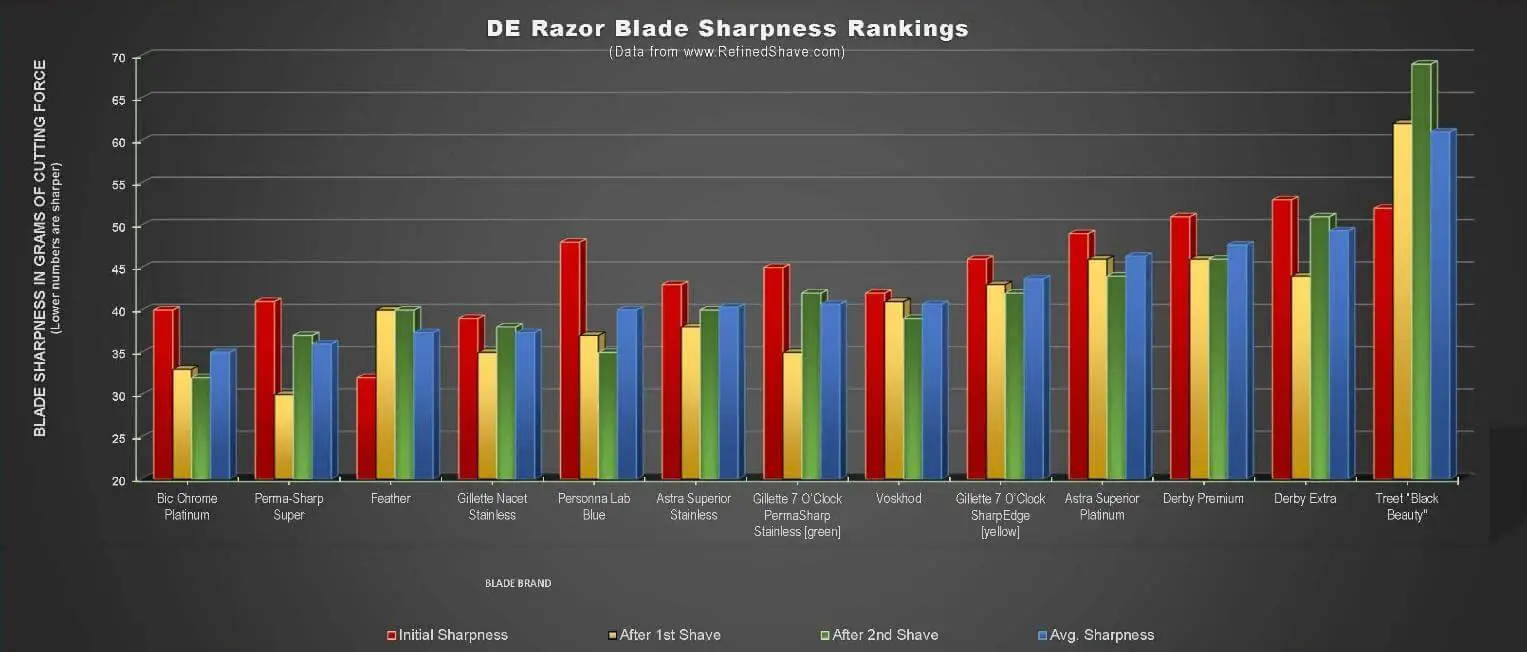

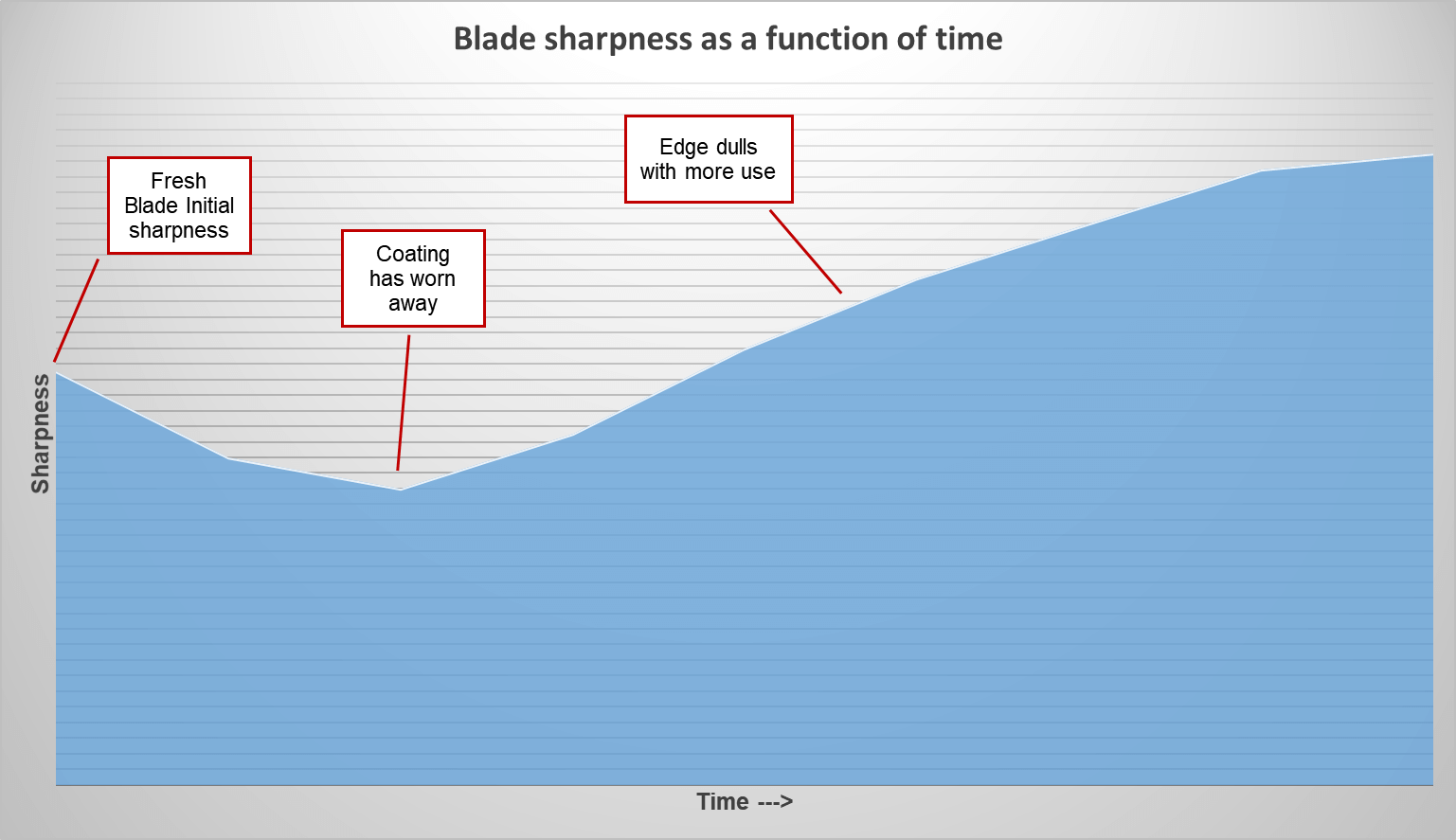

Now, Let’s examine the sharp evidence before us, Dr. Watson! Consider this graph:

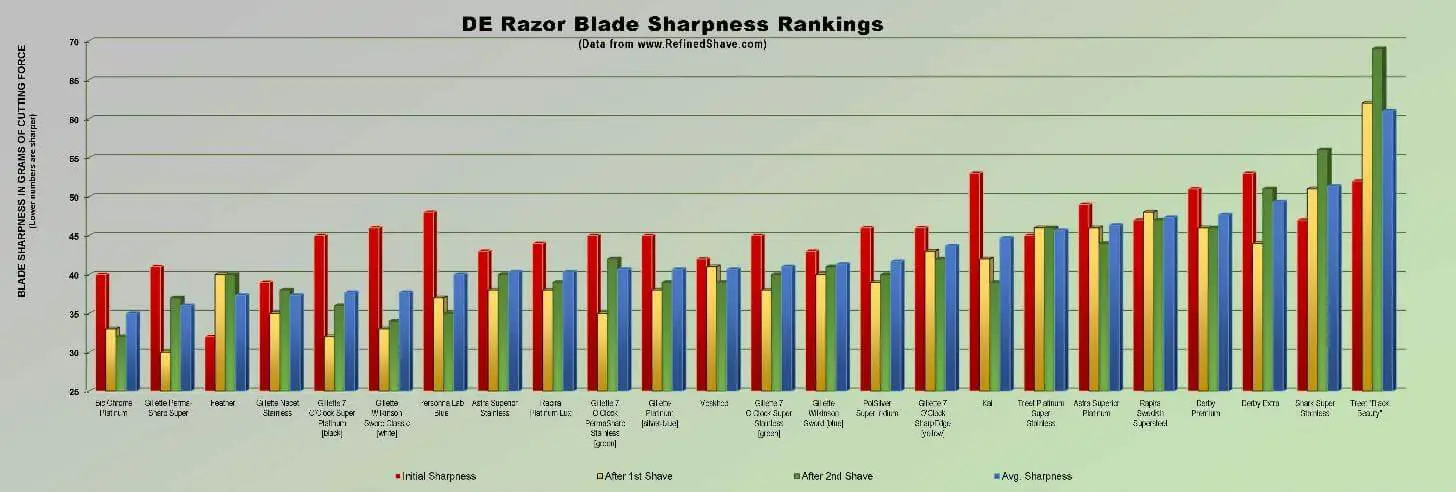

A more complete list of blade sharpness performance will be found here:

(On a side note, based upon this graph, it appears Gillette owns a majority of the double edge razor blade market. Especially when you factor in the various brands – Astra, Voskhod, Wilkinson – which are indirectly owned by Gillette. :-/ )

The terms and details in these graphs ought to self-explanatory, but consider your own experiences as you reflect on this:

- Razors blades in the range of 50 [grams of cutting force] will begin to pull and tug, and may require multiple passes – with subsequent irritation – to fully clean up those areas if they clean up at all.

- Blades in the region of low 30’s will be so sharp that you will tend to get irritation, spots and weepers, especially with sensitive skin, when shaving while or directly after showering, hacking away your neckbeard, or shaving against-the-grain finish passes.

- Ultra-sharp blades of any stripe have the unfortunate tendency to “dive into” the skin when doing the finish pass against the grain. This is particularly problematic for men with sensitive skin and/or shaving on the neck, or when shaving later in the week after earlier shaves exfoliate outer layers of skin.

- My experience is you will wish your blade sharpness to dwell right around 40 on the graph or slightly north thereof, for an optimal balance between comfort and efficiency.

- As always, your mileage will vary according to your skin type, shave frequency, shaving prep and materials, razor type, and toughness of your whiskers.

Most of the information in these charts has a U-shaped graph to it, and will demonstrate a sharpness lifecycle as follows:

(Lower “volume” is sharper.)

The exception to this rule includes blades with little or no coating, and/or soft metal, e.g. the Treet Black Beauty or the Shark Super Stainless. Those blades come to you as sharp as they are going to get, and then get even duller, much like some mothers-in-law. The much-loved Feather blades are also opposite the above graphic, with an extremely sharp initial cutting edge which gradually wears down with use.

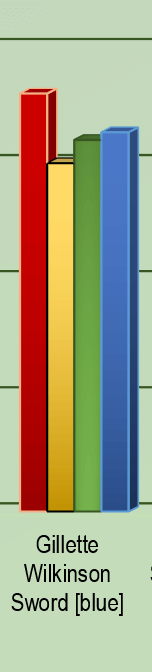

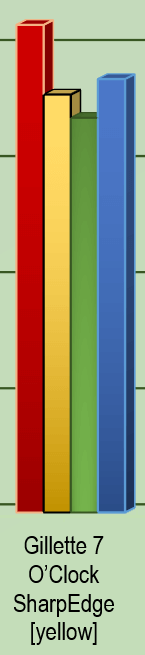

Consider the following examples from the above:

These blades all exhibit the trademark characteristics of a thick coating which wears away quickly to expose the sharp cutting edge. Blades which exhibit these wild swings in sharpness – mild at first but becoming very sharp in use as the coating wears off – will tend to nick more because you will have to change your shave style/pressure slightly to avoid problems with a sharper blade. Unless you have iron skin, which I sure as heck don’t! Some folks handle these fine but others with sensitive skin may suffer.

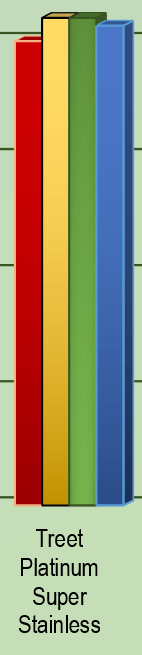

Now examine more consistent blades:

These above blade ratings indicate:

- Minimal wear of blade coating – or little blade coating in the first place,

- Good adhesion of coating to base metal surface,

- A decent blade grind which preserves the cutting edge, and/or

- Good blade hardening and tempering of a good quality stainless steel.

Conclusions

As we say in the field of engineering, numbers don’t lie. Going by the data I’ve compiled in the above graphs, the most consistent blades with the minimal variation in sharpness will tend to be the most comfortable in the long run.

My closing advice to you, dear reader, is invest in razor blades which have the most consistent sharpness using the charts and details above. Then enjoy the zen-like experience of the smoother, closer and better shave.

Happy shaving!

Charles

Author Profile: Charles Smith is a mechanical design engineer, technical writer and wet shaving enthusiast, frequently suffering from the dreaded Razor Acquisition Disorder and trying to refrain from buying yet another high-end shaving instrument or another few tubs of shave soaps. He resides in northeast Ohio with his wife and 2 cats.

The graph for all blades are too low resolution to read any of the words. I have made a higher resolution graphs sorted by alphabetical and by average sharpness here if anyone wants to see it.

Album: https://imgur.com/a/p7Ohw2l

Alphabetical order: https://imgur.com/l19HPd8

Average sharpness: https://imgur.com/sYvGcdH

Great article! Interesting how some blades vary so much between shaves.

For example I found voskhod blades slightly rough on the 1st shave. Then the 2nd shave was so great I couldn’t believe it. However the 3rd shave went down hill very quick.

I like a blade to go for 3 shaves, at the moment I find Astra SP, 7 o’clock yellow and Nacet can do this. Currently had 2 shaves with Rapira Platinum Lux and crossing my fingers it will make 3. As the first 2 shaves have been excellent.

Sharpness is important but smoothness and how long it stays at the sweet spot is very important for me.

This is one of my most favorite articles here!

Interesting article, which finally explains why a Shark blade (among others) has always been simply too harsh for my face. In summary, the article explains why you shouldn’t always go with “the sharpest” blade.

Also, corking simply reduces the number of shaves for a given blade. It wastes the longevity of a blade.

I use two razors. The Feather Stainless and the Rockwell 6s, using the more mild settings of 2 or 3. I use Feather blades. For me, these mild razors with the very sharp Feather blades work best. Less nicks and weepers along with a close shave. I get two to three close shaves per blade.

Very interesting and informative article that triggered a purchase of blades. 🙂

I used Feathers at one stage but found them as a killer blade due to being east to nick your self. After trying many of the above brands on test i found the Astra platinum as a smooth operator for sharpness, longevity and all round performance. What i recon is the most important is face preparation and a quality cream or soap lather.

What is “grokked?”

Fantastic article!

Grok is Martian for understand.

From Robert A. Heinlein’s “Stranger in a strange Land”

There is only one issue that most people totally misinterpret: what they think is sharpness is really smoothness. The sharpness is not important. What is is the ability of the blade to not only slice the whisker but to repel the cut whisker(s) to prevent drag. Drag is the roughness many interpret as dullness. That is why it is oxymoronic to say a blade is sharp AND smooth. Once a person grasps this concept it all falls together.

The different blades by Gillette are merely slightly different hone angles to work in a variety of razors as well as different levels of edge hardness. That is why the better blades impart a sensation of shaving “hard” at first. Of course, that goes hand in hand with the coating “pull back” initially as well also.

The real engineering magic is in the coatings/sputterings/edge hardness and not sharpness.

Perfectly stated. This is very likely one of the roots of the UNIVERSAL shaving truism; YMMV

I get a great shave using a Feather blade once, then bin it. IF I use a slant razor I get 2 passes before it gets irritating, if I use a linear razor 1 pass is all I get before tugging and pulling. So 2 blades per shave if I want a plesant shave. I have tried other blades, yes the ones in the chart above. Many of them tug and pull right out of the wrapper.

The chart above demonstrates why that is.

Thanks

Great article.

TP

Great article. Thank you. Having the data is very useful. It is especially helpful to understand what happens to blades as they are used. I didn’t realize that many coated blades get sharper with use. I never understood why I seem to get the best shaves on the 2nd and 3rd use. Over the years I have tried many blades and continue to experiment and to re-audition blades I haven’t used in a while. With all of this, my two favorites have not changed — Astra SP in more aggressive razors and Polsilver in milder razors. (Although Polsilver seems to be gone, I have found a local shop which still has several hundred in stock so I scarfed up 200 yesterday.)

Nice article and reference material. With that said, I’m terribly disappointed the main graphs aren’t clickable (they do not enlarge). And those that can be read with the naked eye don’t have enough of legend to make them decipherable.

The one blade characteristic I really want to see explored/compared is the grind angle/bevel across blades. I can’t get past thinking, when the coating wears off, it’s probably the main factor in blade sharpness.

And while engineers may say “numbers don’t lie”, we research professionals know if you torture numbers long enough they’ll confess to just about anything.

And, as aside to Michael Goldweber, nice use of “grokked”. Walt and Don would be proud.

Brian, my bad, images default to non-clickable. I’ve changed that so images in this article can now be clicked to show at their original resolution.

Thanks. Now the graphs make a bit more sense.

And so would Robert Heinlein – who I thought originally coined the term in “Stranger in a Strange Land.”

Great article – thanks for summarizing and graphing the results. Also thanks for turning me/us onto a new shaving site, previously unknown.

Question/Observation: What effect does corking a blade have prior to a blade’s first shave?

A previous Sharpologist article (https://sharpologist.com/2019/02/how-to-cork-a-razor-blade.html) recommended this practice to reduce/eliminate the harshness of a blade’s first shave and remove any microscopic burrs. Correlating that “observational” practice together with this data, one might conclude that corking goes a long way towards removing the blade’s initial coating and quickly transitioning the blade down to its average sharpness.

While I “cork” I (because it does eliminate a blade’s initial harshness), I never fully grokked the proffered explanation: microscopic burrs. Given that a blade is usually coated (Personna Med Prep in my case), are the burrs in the coating? Burrs in the metal?

It would be interesting to see some of this measured testing done on a fresh blade compared to a corked fresh blade.

Comments are closed.